Corporations such as Walmart, Renault Trucks, and BAE Systems are employing immersive technologies to drive efficiencies, and these companies are seeing a strong return on investment.

According to a report from the Capgemini Research Institute, 82 percent of companies currently implementing XR say the benefits are either meeting or exceeding their expectations. This is laying a positive foundation for the widespread business adoption of XR.

The expansion of enterprise XR is being aided by significant investment from the likes of Microsoft, HP, and Facebook. Indeed, with this month’s release of Oculus Quest, Facebook’s new all-in-one VR system, Facebook also announced the relaunch of Oculus for Business – an enterprise solution designed to streamline and expand VR in the workplace. The new software suite offers device setup and management tools, enterprise-grade service and support, and a new user experience customized for business use cases. Facebook is also working on ways to integrate VR alongside the workflows and services businesses already use.

Training

VR-based training programs can reduce training time by 40 percent and improve employee performance by 70 percent, compared to traditional training. Therefore, it’s no surprise that it is one of the most common uses of XR within enterprise – 62 percent according to CompTIA.

STRIVR, a US-based startup developing VR apps, told VRScout that VR can “completely eliminate some of the hidden costs of employee training.” These costs include employee time, travel, facilities, materials, and equipment. Another plus for VR training: costly, difficult, or otherwise-impossible scenarios and simulations become within reach.

Below are some of the forward-thinking companies employing XR training programs.

American retail corporation Walmart has deployed thousands of Oculus Go devices across its workforce for training. The retailer is using VR to train associates in three main areas: new technology, soft skills like empathy and customer service, and compliance. Participants in Walmart’s early VR training program reported a 30 percent higher training satisfaction, versus other training materials and methods. 70 percent of employees who trained in VR outperformed groups trained with other materials and techniques.

Intel, a leader in manufacturing for technology, has to deliver regulatory training on electrical safety. The company partnered with SkillReal to create VR training scenarios. The scenarios place users in a manufacturing plant, where they have to complete specific tasks. The VR program also tracks analytics such as how long it takes trainees to complete tasks and which objects they interact with. Intel estimates a 300 percent ROI potential on the VR course and 94 percent of trainees surveyed asked that more VR courses be made available, demonstrating the demand for this type of training.

Microsoft is developing MR training solutions for companies such as Airbus and JAL. The two airlines are using the HoloLens to train their teams of engineers and cabin crews.

Operations

The unique properties of VR, AR, and MR are generating productivity benefits across a range of industries. Below are just some examples of how immersive technology is being used to streamline workflows, improve efficiency and safety, and help manage the complexity of tasks.

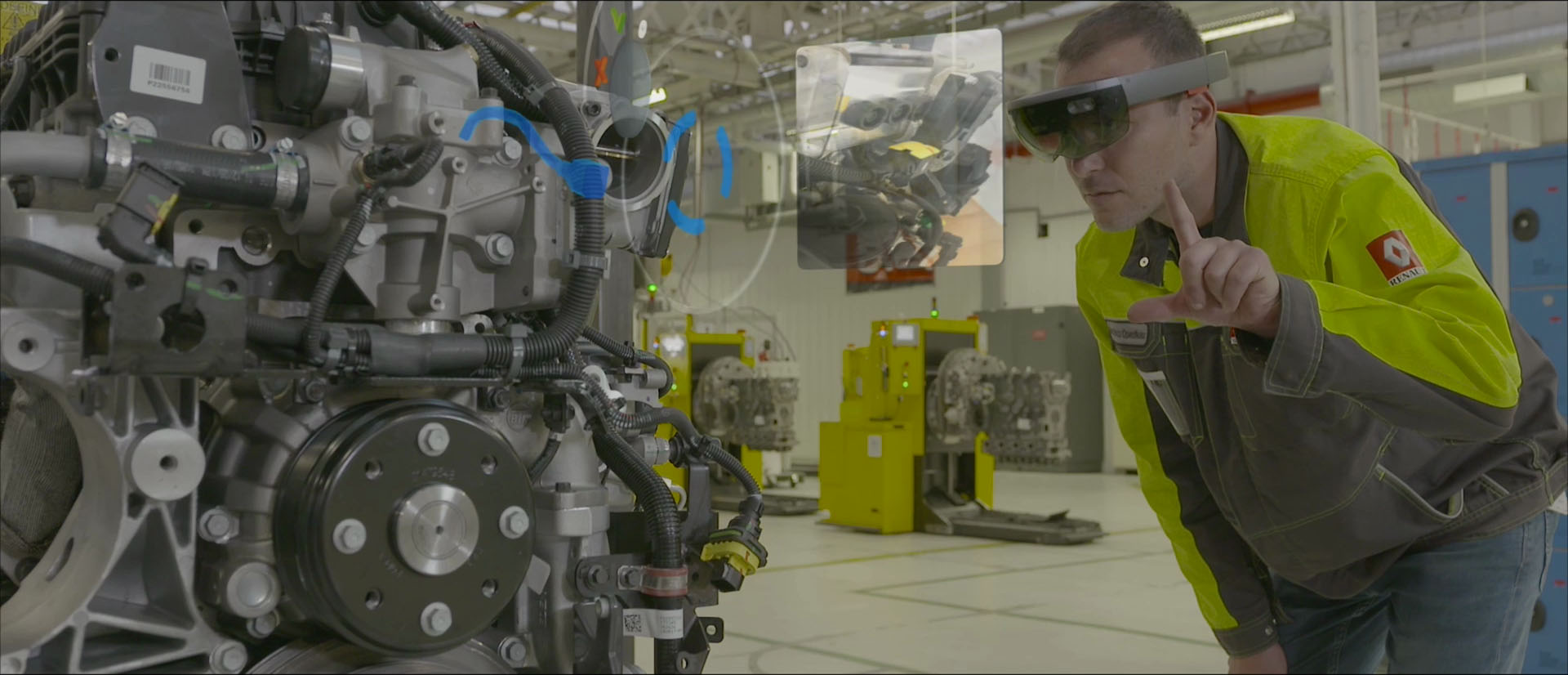

French manufacturer Renault Trucks, in collaboration with technology partner Immersion, has been using a HoloLens at its Lyon-based facility to improve quality control processes with its engine assembly operations. Quality control operators wear a HoloLens in which all the digitalized engine parts are integrated. Via the glasses and mixed reality interface, operators see decision-making instructions that will guide them through the most complex control operations. An engineer leading the project said, “At the moment, operators working on control points are still using paper instructions.” It’s easy to see how the introduction of MR will greatly improve the process.

BAE Systems, a multinational defense, security, and aerospace company, has been using HoloLens in its processes to make electric propulsion devices. BAE and PTC, a global software company, used its ThingWorx Studio to create a guided step-by-step training solution for HoloLens to teach workers how to assemble a green energy bus battery. Using these tools, BAE can now create these guides for first-line workers in just a few hours – at a tenth of the cost.

During a Google Glass pilot, Boeing helped its wire harness workers decrease the assembly time by 25 percent and it significantly reduced error rates. Every Boeing plane contains thousands of wires that connect its different electrical systems. Workers construct large portions of this wiring – “wire harnesses” – at a time. This task demands intense concentration. For years, workers used PDF-based assembly instructions on laptops to locate the right wires and connect them in the right sequence. This meant attention was constantly being shifted between the harness being wired and a computer screen. With the introduction of MR and hands-free interactive 3D wiring, error rates have been reduced to nearly zero and the task is completed much faster.

Trimble, a construction hardware company, aims to correct the amount of time and money lost in the construction process. The Trimble XR10 is a customized hard hat with a HoloLens 2 built in. It enables workers in safety-controlled environments to access model data directly on site and will change the way construction professionals design, build and operate.

These use cases are compelling and show that XR can positively impact businesses, improve operations and ultimately cut costs. Some 46 percent of companies believe the technology will become mainstream in their organization within the next three years, while a further 38 percent think it will become mainstream in their organization in the next three to five years. The major barriers to this adoption will be a shortage of in-house expertise and insufficient back-end infrastructures.

This article was written by Sol Rogers and originally appeared on Forbes.com.